With a specialty chemicals business – where batch sizes are small, custom formulas and strict quality requirements are common – changeover time is often a major bottleneck. For every minute of switching from one batch of product to another, production time, resources and prices go up.

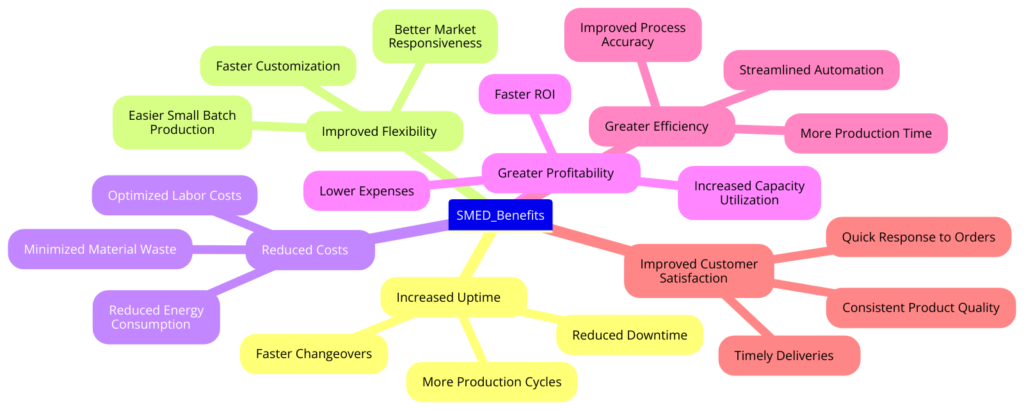

The Single-Minute Exchange of Dies (SMED), a lean manufacturing technique that has been tested, is a workable solution. By streamlining and automating the changeover, enterprises are able to drastically minimize downtime, flexibility and productivity — without spending huge sums of money on capital. In this article, learn about the SMED process in specialty chemicals production and what you can do to make improvements.

Understanding the SMED Method

Shigeo Shingo created the Single-Minute Exchange of Dies (SMED) process to solve one of the biggest manufacturing challenges: long changeover times. It is the goal of SMED to make it as fast as possible to transition from one product to another with a goal of less than 10 minutes (“single-digit minutes”).

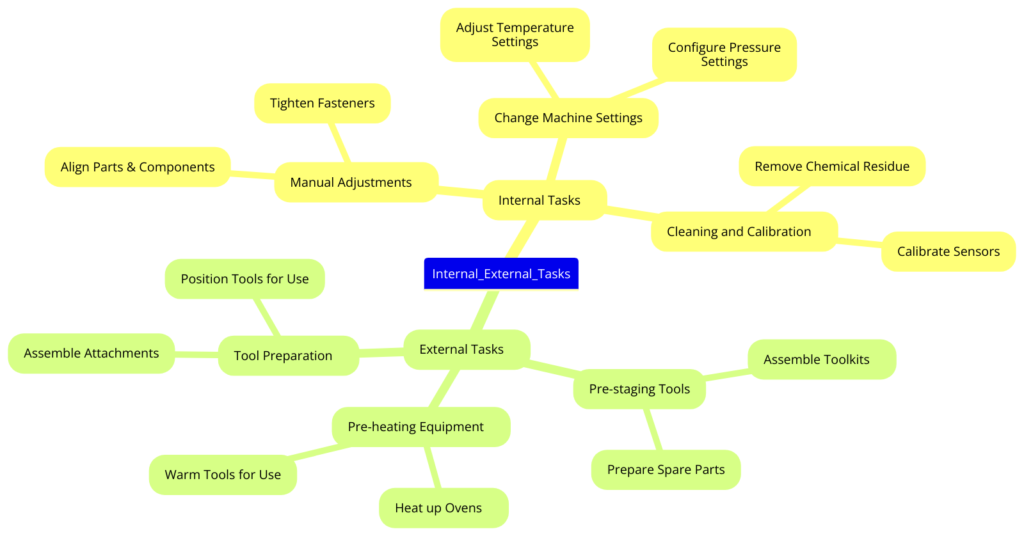

SMED operates by sorting tasks into two types:

Internal tasks: Work that can be done only when the machine or equipment is not being used. These are necessary and inevitable during a switchover but they can be delegated or sped up.

External tasks: Tasks which can be done before and/or after the changeover operation of the machine. We save production time by outsource as much of the work as possible.

SMED is most useful for specialty chemicals manufacturers where batch changeovers are needed frequently to produce custom formulations. These changes include washing machinery, resetting machines and prepping raw materials. They take a huge time and, in the absence of optimization, adds up to high costs, as well as losing customers.

SMED can optimize companies’ process to reduce inefficiencies, standardize processes, and eliminate blunders by conducting a holistic changeover process audit. The end-product is more rapid changeovers, more efficient equipment usage and greater adaptability to the needs of the market.

A specialty resins company, for instance, had six-hour turnaround times due to long cleaning and retooling runs. Through the use of SMED, the company reduced these times to two hours, freeing up more production space and delivering better.

Why Changeover Time is Critical for Specialty Chemicals?

In a business of rigor and accuracy, changeover times are a determining influence on operational performance. Specialty chemicals, in contrast to commodity chemicals, usually come in smaller, bespoke batches. This means constant changes in production processes, equipment cleaning and quality recalibrating — which take time and effort.

Lengthy changeover times present a variety of problems for specialty chemical manufacturers:

Delays: Machines lying idle in changeovers is time lost to production and downtime. For a business making a popular custom coatings, even an hour of equipment sitting in idle could mean lost time.

More Cost: The longer the changeover takes, the more time, money, and energy that is consumed.

Material Wastage: Switchovers involve decontaminating equipment of chemical residues or raw materials, which result in lost material and loss of profit.

A Lower Responsiveness: Long peaks and valleys mean a business cannot respond in a timely fashion to customer requirements, market forces or unexpected production demand.

One specialty coatings manufacturer, for instance, that has specialized batches of colors was experiencing production problems caused by four-hour order-to-order switchover. This not only delayed deliveries, but it also fractured relationships with customers. Changeovers by SMED – from three hours to two – gave the firm greater flexibility in production, customer confidence and a greater ability to make short deadlines.

Changeover times are not just about efficiency; it is actually an indirect consequence of the company’s capacity to compete in a market where competition is ever-higher. Reduced downtime gives manufacturers the flexibility to meet diverse customer requirements with minimal costs and increased production.

How to Implement the SMED Method: A Quick Reference Step by Step

The SMED method provides a methodology to monitor and streamline changeover activities. Once the process is routinely disaggregated, organizations can see where things can be improved and implement solutions that produce tangible results.

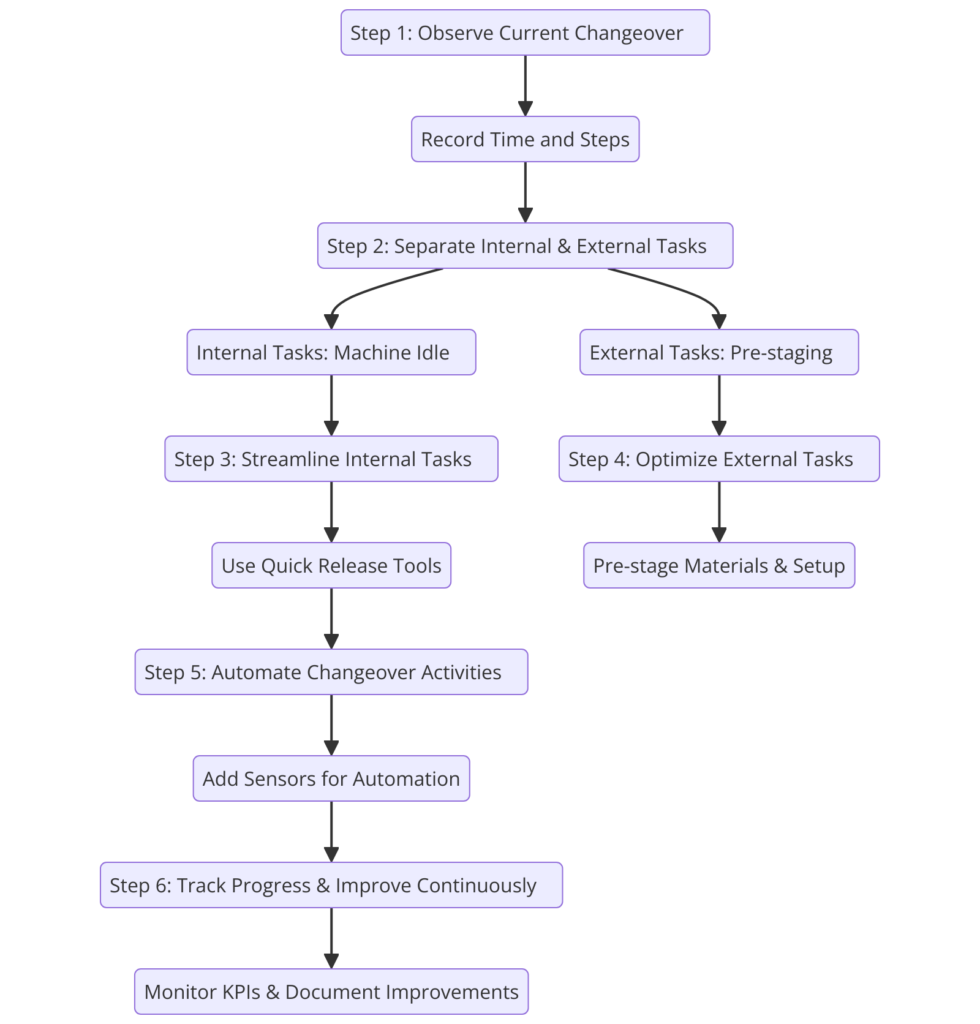

Step 1: Watch and Test the Current Changeover Process

Begin by monitoring in real-time the current changeover. Record all the process, from shutdown to production to start of next batch. Be specific such as what tools are used, time per activity and who is doing each activity. Make operators, technicians, and supervisors involved so that everything is recorded.

A specialty adhesives manufacturer, for instance, found 30 minutes of setup time wasted searching for tools and cleaning equipment. Even this tiny inefficiency added up across many switchovers.

Step 2: Keep the Internal and External Tasks Separated

Divide activities into internal and external. Things that have to be done inside while the machines are down, like changing machine settings, need to be done. External activities such as incoming raw materials or cleaning equipment can be scheduled in advance while the machines are still operational.

It is always quick and time efficient to delegate tasks to the outside world. In idle time can be cut considerably by staging materials beforehand, getting tools set up, and having documentation ready when the machine is idle.

Step 3: Streamline Internal Tasks

Be more simplifying and faster about the tasks you’ll need to do during the switchover. Tools like quick-release clamps, modular fixtures, and standardized tools save time spent changing parts.

One specialty resins manufacturer, for example, switched to quick-connect fittings for mixing equipment, cutting disassembly time in half.

Step 4: Optimize External Tasks

Make sure outside work is being completed on time and at a high quality. Having routine functions (for example, pre-heating or pre-mixing chemicals) automated prevents mistakes and prepares you for the start of the changeover.

Step 5: Automate Changeover Activities

Create a common process for every phase of the optimal changeover process. Make sure to use checklists, graphics and easy to follow steps. Enforce people to do the new procedure, and support its value with clear outcomes.

Step 6: Track Progress and Constantly Improve

Track KPIs – Changeover time, uptime of production, saved labor hours etc. Make sure to periodically check in on the process to see where you can do it better and keep things moving.

Examples of Practical Use of SMED in Specimen Chemicals.

Reducing Batch Changeover Times

A specialty polymers company reduced batch changeover from six hours to two with SMED practices. It used quick-release tooling, trays and automated cleaning systems. This allowed the company to generate further batches per day without having to buy new machinery.

Examples of Practical Use of SMED in Specimen Chemicals

Improving Flexibility in Custom Formulations

One coatings producer doubled changeover times on cleaning and recalibrating processes. The advantage was that the company could move quickly from one custom color formulation to another, better reacting to last-minute orders.

Enhancing Production Throughput

A packaging line switchover process for a specialty adhesives manufacturer made use of SMED. Thanks to modular fixtures and standard operating procedures, set-up time decreased by 30% for the company, while increasing the production rate and saving money on overtime.

Overcoming Challenges in SMED Implementation

Resistance to change is one of the most prevalent obstacles organizations encounter when rolling out SMED. Machine operators and managers can be skeptical of changes to processes or simply find them overwhelming. To break this resistance, it’s important to start with the employees, involve them in the process, and show them how to achieve quick, win-now wins.

It can also be a pain to collect the data especially with complicated workflows. With digital devices like IoT sensors and time-tracking software it becomes easier to count changeover times and they are accurate.

Leveraging Technology to Enhance SMED

Technology gives the impact of SMED more impact by offering real time analytics and automation possibilities. IoT sensors track equipment health, downtime, and power consumption to provide data-based possibilities for optimization. Digital tools such as predictive maintenance software make sure that machinery is ready for production upon changeover.

Supporting and Scaling Changeover Time Decreases

Results from SMED are not the end of the road. Keep improvement going by reviewing the changeover metrics often, training frequently and receiving feedback from the employees regularly. The impact of SMED is enhanced when it is extended to multiple lines and incorporates into the overall operation excellence process of companies.

Bottom Line: Gain Efficiency and Flexibility With SMED

The SMED solution gives specialty chemicals producers a tried and tested way to accelerate changeover, improve efficiency and maximize flexibility. With simplified changeovers, enterprises can avoid downtime, cost and support customer demands more quickly and reliably. SMED doesn’t only work — it is a means to leverage untapped potential and set your company up for long-term competitive advantage.