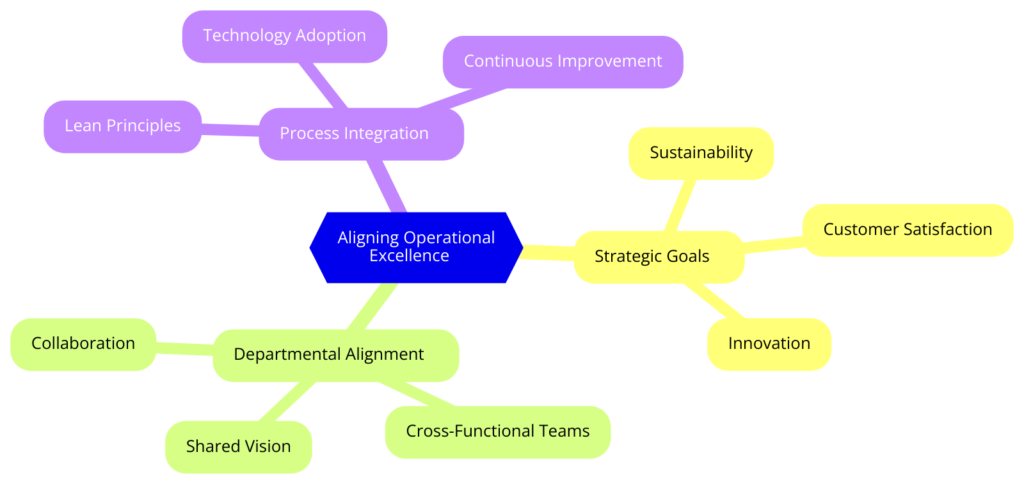

It is a new way to optimize organizational performance, especially in such a dynamic industry as specialty chemicals. Though frequently thought of as efficiency, operational excellence is about more than just saving money and optimizing processes. It is a totality strategy that brings continuous improvement, innovation and flexibility to the foundation of a company’s culture and processes.

Operational excellence for specialty chemicals firms solves production inconsistency, high regulatory expectations, and shifting customer demands. If organizations instill lean values and create a culture of excellence, they can make long-term gains in quality, cost-effectiveness, and competitiveness.

What is Operational Excellence?

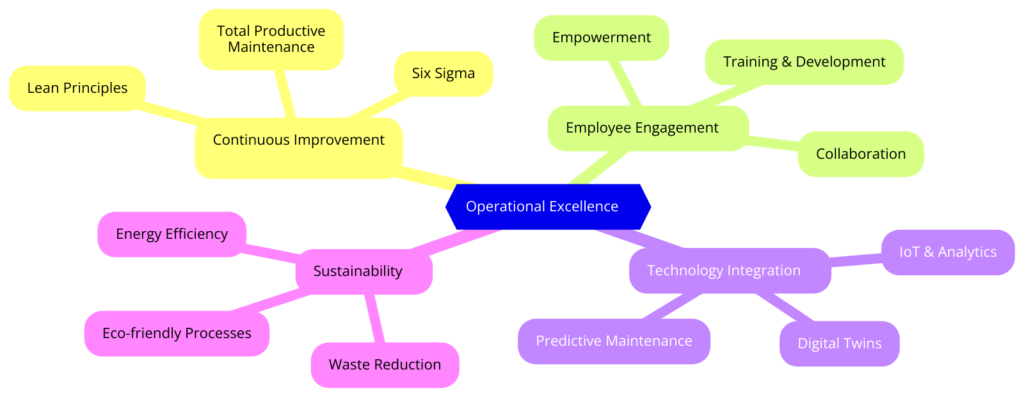

Not only is operational excellence a tool or process, but a mindset and a strategic structure that change the way organizations think, innovate and perform. Operational excellence — is key to managing the industry in which specialty chemicals companies must be accurate, innovative and adaptable.

A Philosophy of Continuous Improvement

Ultimately, operational excellence is about adding value through process optimization, people-centricity and scalability with strategic goals. In contrast to discrete efficiency projects, operational excellence is one that embeds improvement in the organization’s culture, so that improvements are not just temporary but also dynamically changing as the business evolves.

In the case of specialty chemicals, that includes controlling variation in formulae, flexibility to accommodate different customer needs, and compliance with stringent regulations. An industrial polymer manufacturer, for instance, used operational excellence concepts to standardize across a number of production lines, reducing defects by 15 per cent and increasing first-pass yield. Not only did these results improve performance, but they also supported the company’s overall sustainability and customer experience objectives.

The Evolution of Operational Excellence

First, operational excellence was a synonym for manufacturing efficiency: the elimination of waste and optimized processes. As time went on, it has been scaled to more strategic aspects of business performance such as supply chain, customer experience, and innovation.

This change applies particularly to specialty chemicals, where firms are being pressured to invent while balancing costs and environmental and regulatory compliance. Operational excellence is now a single set of standards that cover the entire business from manufacturing to delivery, and which delivers agility and resilience in an ever-changing market.

The Contribution of Culture to Optimal Performance?

Culture is one of the major levers for operational excellence. It defines the approach employees take to problems, how they get along with one another, and how they deal with transitions. It’s a necessity for operational excellence to be based on a culture of continuous improvement, collaboration and responsibility.

This culture is formed by leadership. A specialty adhesives company, for instance, enlisted employees in the celebration of small wins and encouraged them to participate in improvement programs. Creating this kind of collaborative culture helped the company drastically cut production waste and improve worker engagement.

Making an operational excellence culture is likewise about clear communication and commitment at all organizational levels. Workers need to feel they can report inefficiencies, come up with solutions, and become owners of their role in achieving improvements. Training and development are a must to equip teams with the skills and competence to adopt this mindset.

Integrating Lean Principles and Beyond

Operational excellence relies heavily on lean thinking but is more than that because it carries over into the organizational strategy. Lean manufacturing is waste minimization and value maximization, and Six Sigma is variability minimization and quality. Combine them with Total Productive Maintenance (TPM) and digital tools and they form an enabling environment for operational excellence.

In specialty chemicals, applying these values means working around issues such as supply chain complexity and production uncertainty. One specialty coatings company, for example, used predictive analytics to optimize production planning, lowering lead times and delivering products on time. This marriage of lean values and high-tech is an example of how operational excellence results in measurable and long-term improvements.

Key Characteristics of Operational Excellence

Operational excellence differs from conventional improvement programs by focusing on alignment, flexibility and sustainability. It is about building a customer-first company, where every action drives future results. Data is the authority in making decisions and continuous improvement is part of the DNA of the business.

In the case of specialty chemicals firms, this supports an efficiency and innovation double chin. Companies can improve the product quality, reduce workflows, and protect the environment all while preparing to adapt quickly to market demands. Those attributes make operational excellence an organizational game-changer that provides outcomes for all parts of the business.

The Benefits of Operational Excellence

Operating Excellence doesn’t just come with efficiency improvements. Specialty chemical manufacturers who follow this practice tend to benefit in the areas of cost reduction, quality and customer satisfaction. A specialty resins manufacturer saved substantial amounts of money by optimizing its production waste and its use of resources, for instance, thereby achieving improved reliability.

In addition, operational excellence also makes an organization more resilient to external forces like regulatory shifts or customer needs. One specialty coatings company implemented the operational excellence model to deliver sustainability in its daily business, with minimal carbon footprint and highest consistency of product. This synergy between environmental and operational responsibility shows the power of operational excellence broadly.

Operational excellence helps specialty chemicals companies succeed in a fast-paced and evolving industry by inculcating a culture of continuous improvement and orienting operations to business strategy. It is not a set of practices but a whole philosophy that changes the way organizations provide value, invent and grow success.

Operational Excellence – Leader as the Basis of Leadership

Leadership is the bedrock of a successful operation. Leaders are needed to make the change – and that is hard in a sector like the specialty chemicals industry, where quality, creativity and agility matter. Not only is operational excellence about tools and processes but a culture in which continuous improvement is the natural order of things. Leadership provides the vision, direction and focus to infuse this approach into the DNA of the organization.

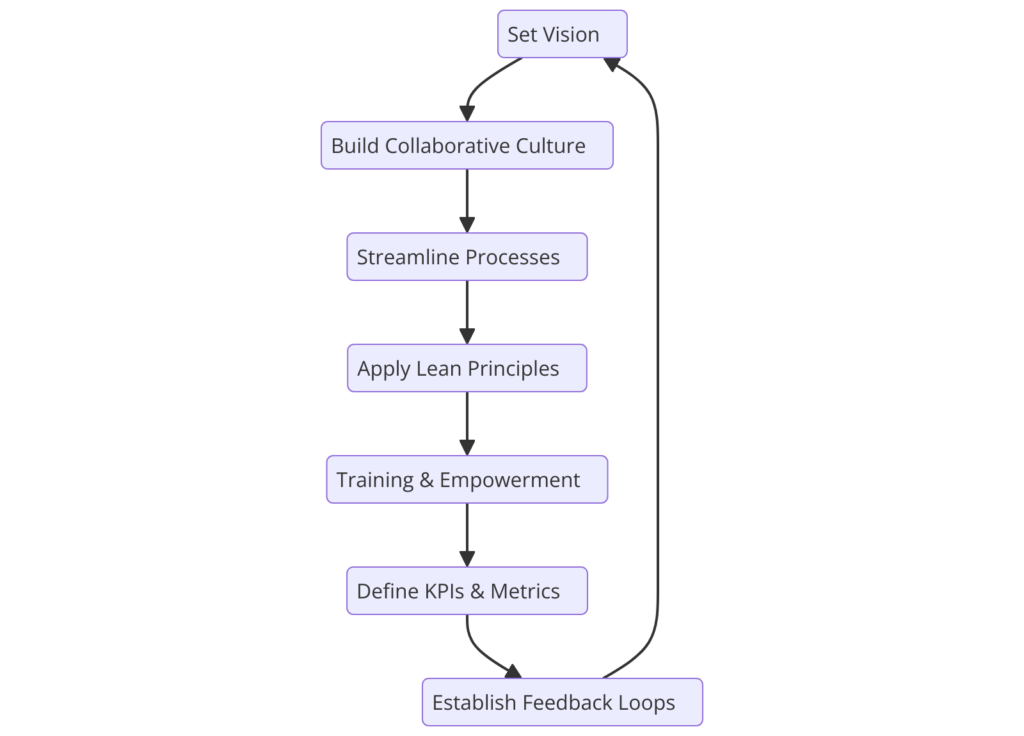

Establishing a Clear Vision

Any operational excellence journey starts with an inspirational vision. Directors need to deliver a vision that is inspiring and can tie the principles of operational excellence to the company’s business strategy. It is a vision that should be shared with employees at every level so that they can know how their work aligns with the mission of the company. In the specialty chemicals industry, this could be by conceptualizing operational excellence as a way to create sustainability, better products or more satisfied customers.

One specialist polymers producer, for instance, was under pressure to be greener. Leaders defined operational excellence as a means of meeting sustainability objectives and talked about how lean principles could reduce waste, save energy and align with environmental goals. This vision inspired workers to work collaboratively for a common cause that encouraged teams to drive innovation.

A solid vision also means departmental alignment. And a big problem for specialty chemicals companies is siloed business, where teams are focused on different goals. If leadership can create a common vision, it’s possible to dismantle these silos and bring people together in common purpose.

Demonstrating Commitment

Leadership commitment is important for staying on course. Effective working usually involves breaking the mold and so will always meet resistance from the workers or managers that are used to how things are. Leadership needs to show it, by actively participating in improvement activities and visibly coaching teams through the transformation journey.

This dedication can be in the form of taking part in Kaizen events, lean trainings or tracking metrics on a regular basis. One specialty adhesives company, for instance, was initially put off by middle management after undergoing a lean transformation. For this reason, the executive team had gone on-site to workshops for improvement, collaborating with employees to spot inefficiencies and drive improvement. Their direct involvement made operational excellence the message that would stick, which sparked trust and support.

It goes beyond investment. Leaders need to be sure that teams are properly armed, trained and supported. This might include investing in efficient technologies like predictive maintenance or real-time performance monitoring dashboards and offering lean consultants or experts who can coach you through the change.

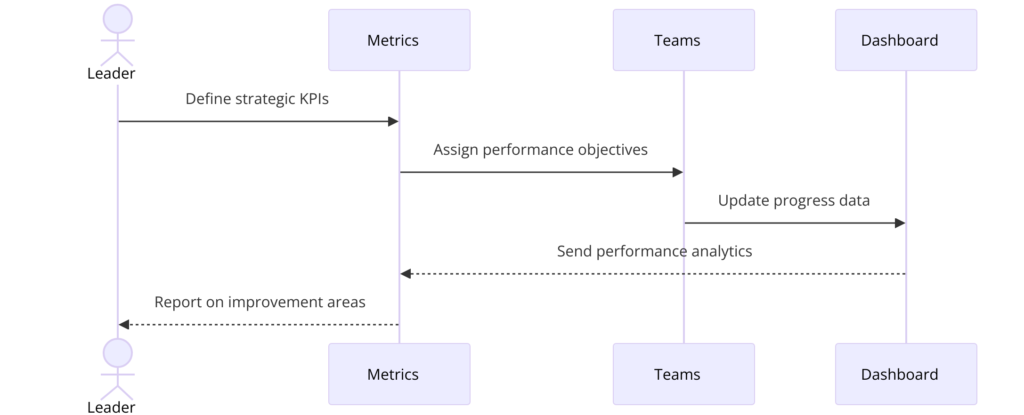

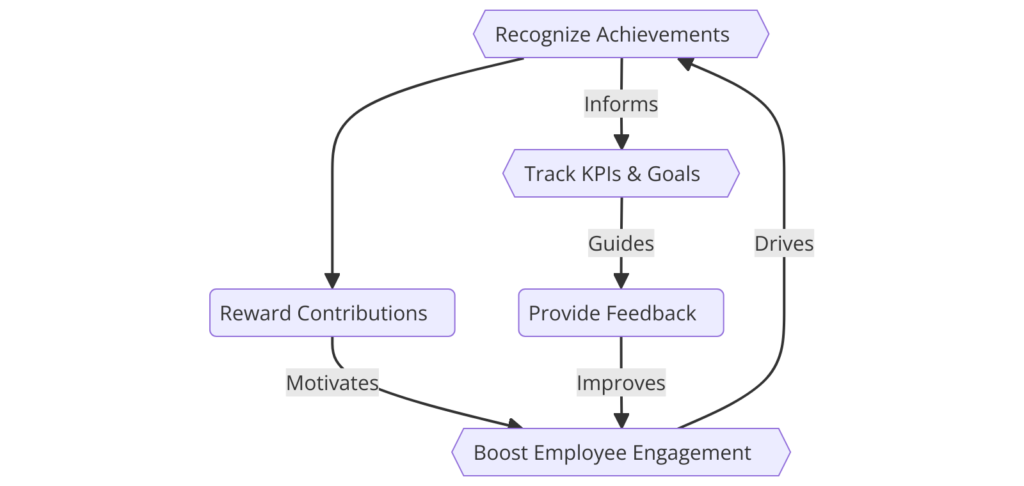

Accountability: Driving Results Through Metrics

Accountability is a fundamental component of operational excellence leadership. Leaders need to entrust results to themselves and their people. This means incorporating operational excellence measures into performance measurement and aligning incentives with improvement objectives. For instance, a specialty resins company associated managers’ bonuses with specific KPIs like the percentage of production waste reduced or first-pass yield increased. This way leaders were still committed to the organization’s purpose.

There’s also accountability in the form of setting measurable objectives and measuring results. Leaders can use data to evaluate how much improvement projects have helped and where they can improve. On-going checks on performance indicators like overall equipment effectiveness (OEE) or lead times will tell you what’s working and what needs tinkering. With the right culture of data, leaders can keep operational excellence a perpetual, process-based journey.

Leading by Example

The leader who sets the example for the behaviors they want their team to perform creates the conditions for a successful change. That is to have an attitude of continuous improvement, seek feedback, and show you are open to change. When managers are engaged in improvement initiatives and apply lean to their own organizations, they lead by example.

One specialty coatings company, for instance, struggled to get its employees involved in the lean process. The CEO started to take stand-up meetings on the production floor every day and talk with teams about where things were going, asking for their feedback on problems and opportunities. The visible leadership also motivated employees to own their part in the change, and created a spirit of cooperation and creativity.

To lead by example is also to communicate transparently. Leaders should make progress announcements, highlight successes and admit failures. This openness creates trust and keeps employees engaged and excited during the change.

Recognition: Celebrating Success

Recognition can be an effective way to energize positive habits and keep the momentum going. Successes need to be rewarded from the top down, from the individual to the team to the organization. It is morale-boosting and also reminds employees that continuous improvement is the key to a healthy workplace when they see employees who embody operational excellence.

One adhesives specialty firm, for example, started a formal recognition program for employee contributions to lean. Every month, the leader’s team picked a “Lean Champion” from the employees and celebrated them in company-wide meetings. Not only was this program an incentive for employees, but it also felt as though the employee played a part in the company’s pursuit of operational excellence.

Overcoming Resistance and Building Trust

Things don’t go so well if you aren’t moving the needle, especially in industries that are used to doing things the way they always have. And it is leaders who help to overcome this resistance and foster trust. That includes taking employees’ feedback, correcting myths and making clear the benefits of operational excellence.

You really need the leadership when things go wrong. Leaders must stop blaming when something doesn’t go their way and turn it into a teaching moment and a place to problem-solve. Leaders that are empathic and pragmatist can help insure employees are comfortable trying new things, experimenting and playing a role in the company’s success.

Developing a Culture of Operational Excellence

It doesn’t stop when operational excellence projects are in place; it keeps on as the company keeps improving and adapting. Leaders need to be on top of the game and constantly evaluate results, change course and keep the company’s belief in a continuous improvement culture.

One is to keep communication and engagement up. Leaders should share case studies, best practices, and report regularly on the results of operational excellence projects. This keeps the organization on target and operational excellence is a foundational part of the culture.

Inspiring Change and Sustaining Momentum

Leadership is operational excellence, it delivers vision, investment, and responsibility to inspire change. When it comes to specialty chemicals, complexity and accuracy are priorities, and a good leader will help make operational excellence projects meet strategic goals, bring people on board, and create value. When leaders do this, exemplify this, celebrate the success and promote a culture of improvement, they’ll have a stronger and more productive organization that is invigorating in a dynamic marketplace.

Embedding Operational Excellence into Processes

This is the foundation of operating excellence. When it comes to the specialty chemicals industry, integrating operational excellence into processes is not just about efficacy. It needs to be a full-cycle solution, coordinating the production processes, quality control, and compliance with organizational objectives and with the industry’s inherent complexity.

Typical specialty chemicals suppliers have special hurdles as products are custom-made, the regulations are strict, and production is highly inconsistent. Implementing operational excellence in processes means these problems are addressed and value delivered consistently to customers.

Identifying and Eliminating Inefficiencies

A good place to start implementing operational excellence is by finding the inefficiencies in processes. This usually means mapping processes to identify bottlenecks, redundancy, and duplication. Value stream mapping, root cause analysis, etc. are tools that can be used to map process flow and highlight where it could be improved.

One specialty resins manufacturer did a value stream mapping exercise for the production line, for instance. This study found huge delays in raw material processing which were impacting downstream process. Automated material transfer and inventory control decreased lead times by 20% and raised throughput.

Beating waste goes further than just operations, order processing and reporting. One specialty polymers firm, for example, simplified the order-to-delivery process through automation of paper work and integration of ERP system with production scheduling. This eliminated manual blunders and helped departments to work more efficiently so responses were delivered faster and the customer satisfaction was greater.

Streamlining Compliance and Quality Control

Specialty chemicals manufacturers live in a highly regulated environment and safety, environmental and quality requirements cannot be argued away. Compliance can take time and be resource-hungry, leading to productivity slowdowns. Implementing operational excellence into compliance processes reduces these issues while adhering to regulations.

A solution is a digitization of compliance activities through on-boarding software solutions. They automate data collection, documentation and reporting, which eliminates admin work and ensures accuracy. A specialty coatings company, for instance, established a compliance management system that centralized all regulatory data. This allowed for auditing to be shorter and the company to react faster to regulatory shifts.

Control of quality is another important element of operative excellence. Integration of QAM within production process assures repeatability and minimization of defect risk. One specialty adhesives manufacturer introduced real-time quality control systems that spotted deviations before they got worse. This proactive effort saved 25% in rework and was better received by the customer.

Optimizing Production Workflows

The process of manufacturing specialty chemicals tends to be characterized by variation, small production quantities and customization. How to make these workflows work best means keeping both cost-effective and flexible enough to adapt to different customer needs. Operational excellence offers the means and processes to strike this synthesis.

Standardized work and just-in-time production are some of the tools in a Lean workflow. A specialty polymers firm, for instance, standardized batch changeover processes that significantly reduced the interval between runs of production. The boost helped the company produce more without deploying new machines or hiring more people.

Predictive maintenance integrations into production workflows are another way to embed operational excellence. When companies monitor the health of equipment using sensors and analytics, failures can be planned and avoided, which reduces costly downtime. The 30% decrease in breakdowns due to predictive maintenance at a specialty coatings company resulted from improved production quality and cost savings.

Integrating Technology for Process Optimization

This is not a stretch to describe the contribution that technology makes towards enabling operational excellence. Digital capabilities like advanced analytics, machine learning and IoT equipment are used to visualize process performance in real time and make data-based decisions. They are a way for specialty chemicals companies to find inefficiencies, measure results, and streamline the business.

A specialty resins company, for example, harnessed the power from advanced analytics to optimize energy use in several locations. Through a pattern analysis of energy use, and the scheduling of equipment changes, the firm saved 15% on energy usage without affecting production volume.

The process optimizer can also take advantage of digital twins — the virtual replication of physical operations. One specialty polymers company used digital twin technology to model and optimize production processes to see where waste could be eliminated and where resources should be allocated. The effect was to increase production productivity by 10% and thereby save a lot of money.

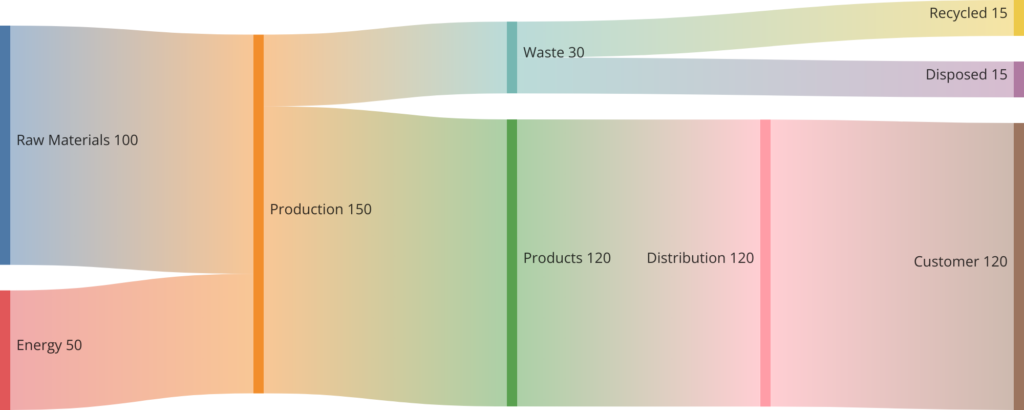

Embedding Sustainability into Processes

High-performing manufacturing in specialty chemicals has to consider sustainability objectives too. The reduction of waste, energy savings and environmental footprint are all growing concerns for customers, regulators and investors alike. Integration of sustainability into business aligns business objectives with the larger ones.

A specialty coatings manufacturer, for instance, repackaged using recyclable materials and removing excess packaging. This initiative reduced material costs while at the same time underlining the brand integrity of the company.

And sustainability can be baked into production processes. One specialist resins company improved solvent recovery so that less was produced and the product was reused in subsequent batches. This circular solution was both sustainable for the company and cost-effective.

Developing a Culture of Continuous Improvement

Incorporating operational excellence into processes isn’t a one-off endeavor; continuous improvement is the culture. Enterprises have to inspire workers to spot bottlenecks, propose fixes, and own process changes. This can be training teams on lean principles like Kaizen and value stream mapping and creating spaces for employees to exchange and work together.

One specialty adhesives company set up weekly improvement meetings in which teams could share suggestions for streamlining workflows. The process inched into many incremental improvements, like streamlining storage layouts and making cleaning easier. These little tweaks all translated into big increases in productivity and employee loyalty.

Continual monitoring and improvement makes operational excellence adaptive to change. Businesses that have this kind of attitude towards innovation are more flexible to change based on market conditions, technologies, and customer requirements.

Transforming Processes into Strategic Assets

Integration of operational excellence into processes reshapes the way specialty chemicals businesses work, innovate and win. Organizations can dramatically improve efficiency, quality and sustainability by proactively removing inefficiencies, improving compliance and quality management and using technology. This holistic approach provides not just short-term profits, but also long-term resilience and success in a highly competitive industry.

The Importance of Employee Engagement

The fuel of business success is employee participation. Leadership offers vision and guidance but it is employees — especially those on the ground — who ensure the actual execution of improvements. Empowered employees bring energy, commitment, and creativity to the workplace – and are indispensable assets on the road to operational excellence. Working at scale in the specialty chemicals business, where variability is often the rule, empower and engage workers to continue to improve continuously.

Developing an Ownership and Accountability Culture

At the root of employee engagement is the development of a culture where employees are ownership and accountable for their work. It is the shift from a model of top-down management to one where all staff at every level are empowered to find inefficiencies, suggest solutions, and be actively engaged in making changes. Workers that are aware that what they do matters directly to the overall mission will more readily be motivated to take ownership of their roles and consider operational excellence as a shared purpose.

A specialty resins manufacturer, for instance, was frequently stalled in its line because of inconsistent cleaning across shifts. Rather than mandate new processes from the top, the company put together a cross-functional group of operators and supervisors to diagnose the problem. They combined to create a standardized cleaning process that minimized downtime by 20 per cent. Since the employees were directly part of the solution creation, they became personally responsible, and the new process would be adhered to for years.

Training and Development for Employees to Build a Powerful Team.

Team engagement starts by giving teams what they need to know and be able to contribute in a meaningful way to operational excellence projects. This capability can only be developed through training and development programs. In the specialty chemicals sector where the processes are often complicated and highly specialized, good training needs to go beyond the theoretical to include practical practice and application.

Lean techniques like 5S, Kaizen and value stream mapping can also be useful in letting your employees find and eliminate waste. A specialty coatings company developed a training program based on these principles, which included both classroom instruction and on-the-job workshops. Within months, workers started reporting dumping and suggesting changes, such as equipment layout and batch sequencing. These grassroots efforts made a huge impact on productivity and showed why employee development was worth the investment.

The empowerment of employees also relies on constant learning. The ability to engage employees and keep them on a skill growth path through mentorship, online training or certifications is another way to ensure that they’re ready for anything new. For instance, one specialist polymers company gave its workers a certification course in advanced manufacturing methods. It was well attended, and the new skills of the staff were used to optimize processes and reduce variability in production.

Fostering Collaboration and Inclusivity

Operational excellence exists only in an atmosphere of teamwork and inclusion. Engaged workers are more likely to share knowledge, work cross-departmental and collaborate on solving difficult issues. This culture of collaboration requires creating channels of free communication and dismantling the silos commonly found in large organizations.

Collaboration can be stimulated with cross-functional teams. A specialty adhesives company created cross-functional Kaizen teams to address specific issues like shortening lead times and inventory. By bringing together workers from production, quality control and supply chain, teams built a solution at the source rather than just symptoms. That synergy not only eliminated inefficiencies but also improved departmental relationships to improve the overall organization.

Inclusivity is equally important. Providing every employee, no matter their position or tenure, a say in any improvement efforts helps create the feeling of inclusion and participation. An advanced chemicals manufacturer, for instance, set up an “idea pipeline” in which workers provided ideas for how to do things better. Each thought was examined by a special committee and employees whose suggestions made it into practice were honored in company meetings. Not only did this project lead to innovative solutions, it also reiterated that the contribution of all employees is respected.

Recognizing and Celebrating Contributions

Recognition is the strongest motivational factor of employees. Employees who understand that they are noticed and valued are also inspired to make the organization successful. It can be anything from a thank-you note to an award and bonus.

A specialty polymers company had a rewards program for workers who demonstrated outstanding operational excellence. One team member was chosen as the “Excellence Champion” each month and was featured in the company newsletter. Winners were also encouraged to pitch at quarterly leadership meetings. This simple but effective program not only improved morale but reinforced the organization’s drive to improvement.

It’s just as crucial to celebrate team wins. For example, after a specialty coatings company had reduced its production waste by 30 per cent, management celebrated the event with all the production employees. This recognition of collective work brought solidarity and motivated employees to improve.

Engaging Employees in Problem-Solving

Achieving operational excellence hinges on problem-solving down to the root cause. This is why it’s essential to get workers involved as they are usually the first to see inefficiencies and can propose practical solutions. By giving workers formal problem-solving techniques, like the A3 process or the Plan-Do-Check-Act (PDCA) cycle, it ensures their suggestions are translated into action.

An industrial adhesives manufacturer applied the A3 solution for an underlying batch quality issue that they repeatedly experienced. Operators were encouraged to attend root cause analysis meetings, where they found that equipment calibration was the main culprit. As a result of their recommendations, the calibration schedule was adopted, solving the problem and making the product more consistent. This learning empowered employees to be their own quality problem solvers and improved their trust in implementing operational excellence efforts.

Creating a Feedback Loop

Employee involvement is maintained through communication and feedback. This keeps leadership connected to their employees and can address issues early on, so you can continue to seek input and get the answers back. This feedback cycle also confirms that operational excellence is a collective process.

For instance, one of the specialty resins companies ran quarterly employee surveys to get their views on lean transformation activities. These questionnaires revealed where workers were left behind, including lacking access to tools and materials. Management used this information to focus changes that helped increase efficiency and enhanced trust and satisfaction among employees.

Sustaining Engagement Through Transparency

Employee engagement requires transparency over time. When people see the concrete outcomes of what they do, whether it’s decreased waste, better quality, or increased customer satisfaction, they are more likely to stay on board with operating excellence. Regular updates, milestone celebrations and discussions of problems keep employees engaged and inspired.

One specialty coatings company used digital dashboards to report on production efficiency and waste reduction in real-time. Workers could observe how their work had impacted the company, giving them pride and evidence that what they’d done was worthwhile. And town hall meetings on a regular basis gave leaders more time to celebrate achievements and set the agenda.

Empowering the Workforce to Drive Excellence

Investing in employees is a key to operational excellence. Through the creation of a culture of ownership, training and support, collaboration and appreciation, specialty chemicals manufacturers can give their employees the opportunity to make real and long-term improvements. Engaged employees do not just make your operation more efficient, they also make you a more creative, resilient, and customer-oriented company. This collaborative process is what makes operational excellence not a practice, but an attitude of success that endures.

Measuring and Sustaining Performance

Performance measurement and optimization are the keys to operational excellence. When improvement activities are not measured well and are not reinforced, they will slow down and do not create value over time. Because in specialty chemicals we are constantly innovating and the market demands more precision and complexity, being able to measure performance is key to ensuring that your operational excellence initiatives are still focused on strategic goals and are not left behind in response to changes in the market.

Performance measurement gives companies a way to stay in sync, pinpoint areas of inefficiencies, and assess the effect of changes. Maintaining performance is a process of integrating these metrics into the culture of the organization to provide a feedback loop, whereby accountability is raised and continuous improvement is a possibility.

The Importance of Performance Metrics

Operational excellence is founded on the metrics. They offer real-world data-backed information on how things are working, and where it can go better. Specialty chemicals metrics need to capture the special problems of the industry — production fluctuations, regulatory compliance, and customer-specificity.

Typical efficiency, quality, and responsiveness KPIs are overall equipment effectiveness (OEE), first-pass yield (FPY) and lead time. So, a specialty coatings company for instance focused on OEE as part of their operation excellence strategy. In response to downtime and production line fluctuation, the company raised OEE from 65% to 85% over the course of a year, resulting in productivity and cost savings.

Measures also help drive operational excellence projects into the corporate objectives. One specialty resins company, for example, had mapped its waste reduction on a continuum with sustainability targets, by keeping track of material use. This made sure that the project improvement did not just improve efficiency, but was also part of the company’s environmental consciousness.

Establishing a Comprehensive Measurement Framework

Implementing a full-scale measurement strategy entails choosing the metrics, setting achievable goals, and making sure that data is consistently collected. It must have a neutral assessment of performance — efficiency, quality, customer satisfaction, sustainability.

In specialty chemicals, that may include multiple tiers of metrics. Operational metrics like cycle time or defect rates are for the day-to-day performance and strategic metrics like customer retention and energy usage indicate the long-term impact of an operational excellence initiative.

Automation and digital tools are also proving crucial for measuring in the new era. New analytics platforms and real-time dashboards let organizations keep tabs on performance metrics in real time, so they can quickly see where the focus is. An adhesives specialty manufacturer, for instance, had an online production monitoring system that monitored production real-time. This made it easier for teams to spot issues early, minimizing delay and making products more stable.

How Benchmarking Can Help Maintain Performance?

Benchmarking is one way to keep performance going and constantly improving. By benchmarking performance against standards or best practice, specialty chemicals manufacturers can see where there’s room to improve and set big but realistic targets. Benchmarking also creates an environment of competition and creativity that motivates the teams to improve.

An industrial manufacturer of specialty polymers, for instance, consulted benchmarking to measure its energy efficiency against competitors. The analysis showed where it could be used to maximize the utilization of equipment and deploy energy saving technologies. These improvements led to a 15% energy reduction over the long term and placed the company on the map for sustainable operations.

Creating a Continuous Feedback Loop

Performance must always follow through on a feedback loop from observation to execution. This means regularly checking metrics, trends, and applying learnings to improve process and strategy. Feedback loops make operational excellence projects dynamic and adaptive to change.

This feedback cycle includes regular performance reviews. One specialty coatings company had monthly production monitoring reviews, and interdepartmental teams met to review performance and recommend improvements. The outcome was not only better decision making but it also strengthened the company’s focus on business excellence.

There should be feedback from workers too. As workers, frontline workers know about what goes on in the work flow. Encouragement of employees to give feedback in team meetings or on digital channels makes sure that their input guides change.

Recognizing Success and Reinforcing Accountability

The only way performance will persist is by being recognized and held accountable. Grasping accomplishments like a specific waste reduction target or production efficiency benchmark help instill the virtue of operational excellence initiatives and encourage employees to keep going.

One specialty resins company, for instance, held quarterly town halls to recognize the success of teams. These were the meetings where managers presented status updates, acknowledged individual efforts, and discussed how operational excellence programs contributed to the company’s overall goal. This open, fun spirit created pride and also compelled employees to stay.

Accountability makes sure metrics are what create change. Metrics built into performance evaluations and incentives aligns the goals of the individual and team with the organization’s goals. A specialty adhesives company correlated manager bonuses with specific KPIs (e.g., downtime reduction, higher first-pass yield). Such alignment also meant that operational excellence was at all levels of the company.

Leveraging Technology to Sustain Performance

It’s technology that keeps things running. Digital devices like predictive analytics, IoT devices, and machine learning algorithms allow companies to track performance indicators constantly and act on it based on data. These technologies aren’t just able to show, but they can give real-time data that spurs change.

A polymer specialist for example used IoT sensors on its production machines to monitor utilization levels and identify bottlenecks. Through the real-time information, the company could streamline scheduling and maintenance which translated into a 10% increase in production capacity and a huge reduction in downtime.

Transparency and collaboration are also at the service of digital transformation. Cloud-based services allow teams to access performance data from any device and help with cross-company coordination and decision making faster. One coatings manufacturer put its performance data in the cloud, centralizing it so everyone had a copy of the data and could work together on improvement projects.

Maintaining Momentum Through Continuous Improvement

Performance only survives if you commit to ongoing improvement. Operational excellence is not a one-time event, it is a process that changes with the organization and its circumstances. Ensuring that metrics are constantly updated and reviewed keeps them current and in alignment with strategy.

One specialty adhesives manufacturer did quarterly reviews of its performance measurement system, including employee input and revising metrics as priorities changed. Such an iterative process kept the company’s operations excellence programs relevant and effective while markets and customers changed.

Turning Data into a Culture of Continuous Improvement

Performance is the key to operating excellence. With the right measurement environment, a continuous feedback loop and technology, specialty chemicals companies can ensure their improvements create long-term value. The recognition and accountability reinforce the organization’s drive for operational excellence while building the resilience and innovation culture that supports long-term success. This whole-of-business strategy helps businesses to win in an ever-competitive, more challenging marketplace.

The Net Effect of Operational Excellence In Larger Dimensions

‘Operational excellence is much more than a productivity drive at the level of the organization, it extends to outside the organization itself, changing not only the way companies work, but how they connect with customers, the environment and the marketplace. Operational excellence offers specialty chemicals companies more than just measurable performance. It helps an organization better innovate, evolve and take control of an ever-more complex and competitive business.

Enhancing Customer Satisfaction and Trust

This is the most immediate and visible result of operational excellence: better customer experience. Specialty chemical manufacturers work in an industry where quality, trustworthiness and adaptability matter. Operational excellence develops all of this by infusing consistency and responsiveness into the organization’s processes.

For instance, a polymers specialty manufacturer applied lean to improve the processes of production so that variations were minimized and the product was consistent. These upgrades led to less complaints and quicker delivery times that improved relationships with key clients. The client’s clients came to see the business as a reliable partner who could deliver on rigorous performance standards, and so repeat purchases and brand loyalty were a higher priority.

Operational excellence also helps businesses to adapt to special customer needs better. Through process optimization and agility culture, companies can provide better flexibility in product customization and delivery times. Such flexibility comes in handy in the specialty chemicals space where customers often require specialized products for particular applications. One coatings specialty supplier who focused on operational excellence cut lead times by 25 per cent, fulfilling tight deadlines for clients in high-demand industries such as automotive and aerospace.

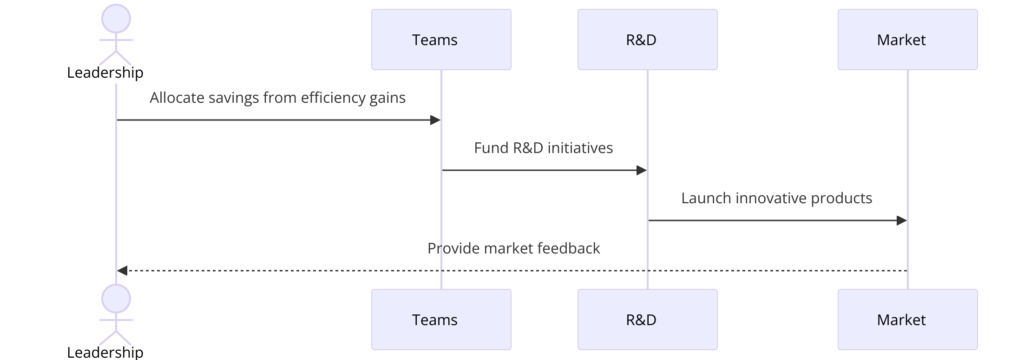

Driving Innovation and Competitive Advantage

Innovation is the bedrock of a perfect business. Streamlining operations and eliminating nasties enable companies to allocate time, people, and money to R&D. This change increases not only internal performance, but also helps organizations stand out from the competition in an ever-changing market.

For the specialty chemicals market where product innovation is a competitive advantage, operational excellence makes room for breakthrough innovations. One specialty adhesives manufacturer, for example, took the savings gained from the lean transformation to spend on R&D. That investment spawned the creation of a novel eco-friendly adhesive formulation that opened new markets and reinforcing the company’s image as a disruptor.

The culture of trial and error that goes with operational excellence also promotes experimentation and problem solving. Engaged employees who are able to suggest change tend to have ideas that make a difference both for the small changes and big changes. If specialty chemicals manufacturers build innovation into the organization’s DNA, they will be ahead of the curve and know what the market will demand in the future.

Strengthening Environmental Sustainability

Specialty chemicals companies are now pressured to cut its emissions wherever possible. This is where operational excellence fits in to these sustainability initiatives by minimizing waste, maximizing the use of resources and optimizing the use of energy. The operating excellence efforts of the organizations that are environmental minded are often also a complement to those efforts and it’s both a win for the company and the environment.

A specialty resins manufacturer simplified solvent recovery operations under its operational excellence initiative. The business minimized waste and re-used components in future production lines by using closed loop processes. In doing so, not only were disposal costs reduced, the carbon footprint of the company decreased substantially as part of its sustainability strategy.

But operational excellence also helps businesses to stay ahead of regulatory standards. One coatings specialty company, for instance, built in digital tools to manage compliance reporting to the environment. This not only cut the administrative time but made emissions monitoring more accurate at real time so the company was in compliance at lower costs.

Not just compliance with regulations, but the combination of sustainability and operational excellence appeals to customers and stakeholders who appreciate eco-conscious brands more than ever. This compliance with the market and society helps build the reputation of the company and offers collaborations and expansion.

Building Organizational Resilience

Change is part of the nature of operating excellence. For a field like specialty chemicals, where raw materials prices are constantly changing, regulations are changed, and customers are changing, operational excellence is the freedom to move through the unknown.

When a culture of continuous improvement and flexibility prevails, operational excellence builds resilience. Firms that do this are prepared for anything, be it a supply chain disruption or a surge in demand. A specialty polymers company, for instance, which implemented predictive analytics for inventory control averted a global supply chain failure. Finding new suppliers and adjusting production times in real time, the firm ran without major interruptions.

This strength extends to the bottom line. In terms of reducing waste and maximizing efficiency, operational excellence enhances profit, even in volatile markets. Specialty chemicals firms that prioritize operational excellence are better suited to weather economic recessions and come through stronger when the economy turns around.

Employee Engagement and Organizational Integrity: Developing Employee Engagement and Organizational Integrity

It is not just processes and metrics that affect operational excellence, it is the culture of the organization as well. Those who work for companies that believe in operational excellence are also generally happier, more fulfilled and more collaborative. That’s because operational excellence creates a space for people to feel valued, empowered and a part of the company’s purpose.

One specialty adhesives manufacturer, for instance, ran a reward scheme to celebrate employee contributions to the lean change. The program emphasized the direct relationship between personal and collective achievement and company aims, building pride and solidarity in the workforce. This eventually improved organizational alignment and decreased turnover, making employees more stable and committed.

Engaged employees are also more likely to see the possibility for change and generate new thoughts, which only serves to keep the needle moving forward. Establishing a culture at work where collaboration, transparency, and respect are all the key elements, operational excellence helps create a path for sustainability.

Matching Market Demand and Trends

What’s more, the effect of operational excellence can be found in how it positions organizations to meet market needs and demands. Customers, investors and others expect more from the companies they patronize: transparency, sustainability, innovation. Operational excellence helps specialty chemicals companies comply with these demands by bringing their internal processes in synch with the external imperatives.

For example, customers in healthcare, electronics and so on value traceability and compliance. One specialty resins manufacturer who adopted digital traceability systems as part of its operation excellence plan was able to stand out in the marketplace by providing more transparency to customers. Such compliance with customer needs not only enhanced communication but established the company as a standout supplier in a competitive environment.

Operational excellence also plays well into the investor interest in certain areas such as ESG (Environmental, Social, and Governance) parameters. Companies with high operational efficiency and sustainability will have higher chances to get investments and partnerships and thereby increase their market presence.

Reaching Beyond Operations to Shape the Future

Operational excellence is more broadly applied in every aspect of a specialty chemicals company’s business, from customer experience and product development to environmental stewardship and corporate resilience. With operating excellence baked into the culture and processes, organizations will achieve new levels of efficiency, agility, and competitiveness. This broader strategy not only produces rapid performance improvements but positions organizations for long-term growth in an industry that is on the rise. Operational excellence is not a corporate initiative but a revolutionary power that helps companies win in the market and make positive impact on society and the world.

Managing for Execution as a Strategic Strategy

That means operational excellence is more than an operational project, it is a strategic imperative that determines the direction of an organization. When you work in the specialty chemicals industry, where accuracy, creativity and adaptability are your lifeblood, operational excellence is the key to long-term success. If you build continuous improvement into the company’s culture and align it with the business goals, you will not only get through the tangle of the industry but also acquire resilience and competitive edge.

An All-Inclusive Way to Get Top Performance!

That is operational excellence — more than just optimizing efficiency or processes. It is an overall strategy, which unifies all facets of an organization (people, processes, technology, strategy) into a system of continuous improvement. This one-stop-shop is particularly important for specialty chemicals firms as the sector has particular peculiarities — large variability of production, strict regulatory compliance and the need for customized solutions.

An adhesives manufacturer, for instance, turned to operational excellence to accelerate production and shorten lead times. Bringing these enhancements to line with the company’s overall strategy for customer satisfaction and market penetration, it scaled rapidly without losing any stability. This convergence between operational and strategic change underlines the transformational force of operational excellence.

Aligning Operational Excellence with Long-Term Objectives

A key characteristic of operational excellence as a strategic imperative is the way it reconciles tactical and tactical activity with organizational strategic initiatives. This alignment allows the right amounts of time to be poured and every project supports the larger purpose of the company.

Sustainability, innovation, and customer satisfaction are usually the main priorities of companies in the specialty chemicals segment. OE gives you the process and tools to bring these strategic aspirations to scale. One specialty coatings company, for example, melded operational excellence with sustainability goals of waste reduction and energy efficiency. These measures not only improved the firm’s environmental performance but also strengthened its position in a market that became increasingly sustainable.

Alignment also creates departmental consistency, eliminating silos and working towards the same vision. A specialty polymers company created cross-functional Kaizen teams to tackle supply chain inefficiencies. This partnership not only led to greater performance of supply chains, but also helped drive the business towards operational excellence as a synthesis strategy.

Driving Innovation Through Operational Excellence

Innovation is the foundation of strategic success and operational excellence is integral to delivering it. When business functions are simplified and inefficiencies removed, companies free up time to devote to research and development. This transforms organizations so that they can be focused on creating value with new products and services.

A specialty resins manufacturer, for instance, utilized the savings it made from its lean revolution to invest in a new, high-performance material. Not only did this technology create new revenues, but it established the company as an innovator. Functional excellence provides the environment for this kind of a forward-looking investment by making sure that foundational processes are effective and stable.

A culture of experimentation and troubleshooting is also part of the organizational culture of operational excellence. Employees who have the ability to spot inefficiencies and suggest changes are often the ones that have breakthrough thoughts and impact small and large-scale transformation. Such innovation culture is invaluable in specialty chemicals, where manufacturers have to be on the pulse of shifting customer requirements and markets.

How to Ensure Resilience in a Bounded Industry

It is the nature of the specialty chemicals market, and raw material prices change, customers evolve, and regulations loom over us. Operational excellence prepares organizations for such complexity through resilience and flexibility. Operational excellence-enabled businesses can adapt faster in any situation, be it supply chain failure, downturn or changing customer expectations.

One specialty adhesives company, for example, implemented predictive analytics to help manage inventory in a way that helped it recover from a supply chain crisis in the world. As the firm identified other suppliers and modified production schedules dynamically, continuity was ensured and customer disruption was minimized. This speed to adapt is one of the strategic drivers of operational excellence for organizational resilience.

Financial resilience too. Using efficiency and waste reduction, operational excellence increases profitability even in hard markets. The operationally minded specialty chemicals firms that can keep up with the storms of the economy are usually better equipped to emerge victorious in a recovery.

Improve Customer Service and Market Share

Operational excellence makes customers’ relationships stronger with consistent quality, timeliness and tailored solutions. Such qualities are important in specialty chemicals, where customers largely depend on suppliers for high-value, one-off products. By incorporating operational excellence into their operations, organizations can satisfy and even exceed customers’ expectations for loyalty and trust.

One of these is a specialty coatings manufacturer, for instance, which employed operational excellence to automate its order fulfillment. With shorter lead times and better product quality, the company made itself more reliable. Customers were beginning to consider the firm a business acquaintance and this translated into repeat customers and market entry.

Functional excellence also improves a business’s competitive advantage by aligning practices with other major industry developments like sustainability and digital transformation. A polymer specialty manufacturer embedded digital tools into production process for better traceability and compliance. This fit with the market not only added competitive advantage to the firm but also drew in new customers looking for openness and accountability.

Enabling Sustainability as a Strategic Agenda

Sustainability is an important issue for any company in any industry, and operational excellence falls in line with these goals. By reducing waste, maximizing resource use and optimizing energy consumption, organizations can save the environment and maximize performance.

One specialty resins manufacturer made sustainability a part of their operating excellence program, by implementing closed loop solvent recovery. This helped reduce waste and emissions in line with the business’ environmental agenda and corporate responsibility. With sustainability forming future customer and investor demands, operational excellence offers a holistic route for delivering.

Implementing a Culture of Continuous Improvement

It is the culture change that operational excellence brings that is its longest lasting effect. Instilling an attitude of continuous learning helps companies set themselves up for long-term success. It is a culture where everyone at every level is empowered to identify the waste, offer suggestions, and own their part in getting the company results.

One specialty adhesives company created this culture by implementing lean principles in every day practice. Teams were also invited to have regular improvement meetings where ideas could be exchanged and progress tracked. This method resulted in many incremental improvements including layout optimization of equipment and easier cleaning. All these small wins added up to big efficiency and employee satisfaction.

A culture of continuous improvement, in turn, ensures that operating excellence is always on-the-move, agnostic and adaptive to the circumstances. The companies who put this mindset first can innovate, evolve and survive in the increasingly competitive environment.

The Cornerstone of Strategic Growth and Resilience

Operational excellence is not a measure of efficiencies, it is a strategic requirement that reshapes the way specialty chemicals companies think, innovate and compete. Operational excellence helps organizations reach sustainable growth and market dominance through a focus on long-term goals, a culture of innovation and flexibility, and resilience to complexity. It is how you will get through today and be ready for tomorrow, and it is a must-have for success in the specialty chemicals industry.