Efficiency in operations is the secret to the specialty chemicals success. This industry has intricate workflows, strict regulatory compliance, and custom-tailored solutions which mean there are always special issues that need to be solved in a different way. Value Stream Mapping (VSM) is one of them — a lean methodology used to discover inefficiencies, automate processes, and align the operations with the business objectives.

This manual is a comprehensive review on how specialty chemicals companies can use VSM to streamline processes, improve performance, and create long-term growth.

What is Value Stream Mapping and Why Is It Important?

Value Stream Mapping is not just a diagram or process map, it’s a plan for how value circulates in an organization. In visualizing every stage of a process, from raw material to the end product, VSM helps businesses spot wastage, optimize processes, and get back to activities that add value to customers.

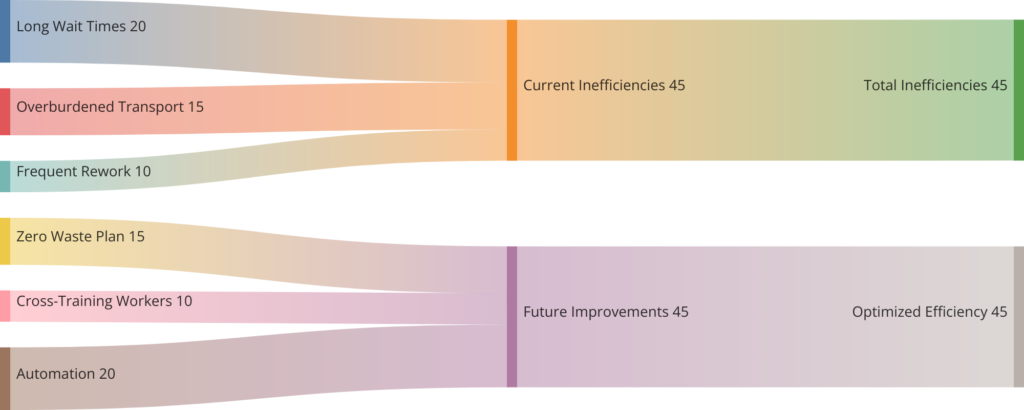

During manufacturing in specialty chemicals with a lot of variability, small batch size and rigorous quality control, inefficiencies pile up. These inefficiencies could be exhibited as long wait times, time-wasters, overburdened materials transport or quality inspections. VSM gives you a visual picture of these inefficiencies so that organizations can target improvements.

One specialty adhesives company, for instance, used VSM to study its batch production system. The test found that there was a major cause of delay – waiting too long between mixing and packaging. As the organization rearranged workflows and communications between departments, overall lead times were cut by 20% leading to higher customer satisfaction.

VSM also helps with departmental collaboration. VSM creates a common language of what teams are contributing to the value stream in organizations where silos obstruct collaboration. This common ground is what enables cooperation and the resultant shared progress.

The VSM Process: Step by Step Instructions

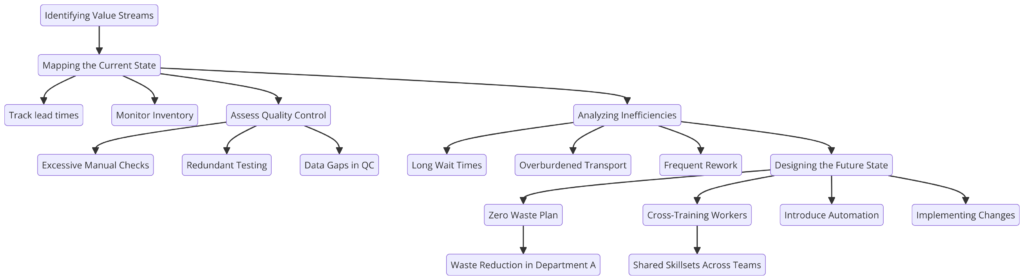

Implementing Value Stream Mapping involves a set of specific processes that are intended to uncover waste and bring organizations to an optimized future state.

Identifying Value Streams

The very first thing you have to do with VSM is choosing the process or workflow you want to study. It’s usually better for specialty chemicals companies to target high impact points, like manufacturing lines, supply chains or R&D workflows. One of the specialty resins companies, for example, targeted order-to-delivery: Production, raw material procurement, logistics. The company also whittled the reach down so that its VSM work would be scalable and effective.

Mapping the Current State

To build a current state map you must have information on each stage of the workflow. These include keeping track of lead times, cycle time, inventory and departments handoffs. Work with workers that are close to the process to ensure that full, detailed data are obtained. This is when companies find the hidden efficiencies, like stock accumulation or regular quality rework.

Analyzing Inefficiencies

Then, having the existing state mapped, the inefficiencies can be found. Check for areas that have inefficiencies, where resources aren’t fully used, or defects. One coatings manufacturer for instance experienced high changeover times that slowed production considerably beyond its industry norms. Once isolated, these inefficiencies could be reduced to changes the business should make most.

Designing the Future State

The future state map is the optimal workflow version. This step is about envisioning a process that is zero waste, zero lead time, and zero inefficiencies. For the specialty coatings manufacturer, the future state map included common changeover processes and cross-training workers to work on various tasks. These reforms streamlined processes and provided more leeway.

Implementing Changes

And going from the present state to the future state takes planning and execution. Delegate clearly, have targets that you can measure and a plan to execute. Always measure results and tweak tactics if needed. One specialty polymers manufacturer had weekly updates on how it was doing and any problems were fixed as quickly as possible.

Case Studies: Real-World Use Cases of VSM in Action

Value Stream Mapping has already been used in many different cases in the specialty chemicals sector. These examples show how VSM has the power to change everything:

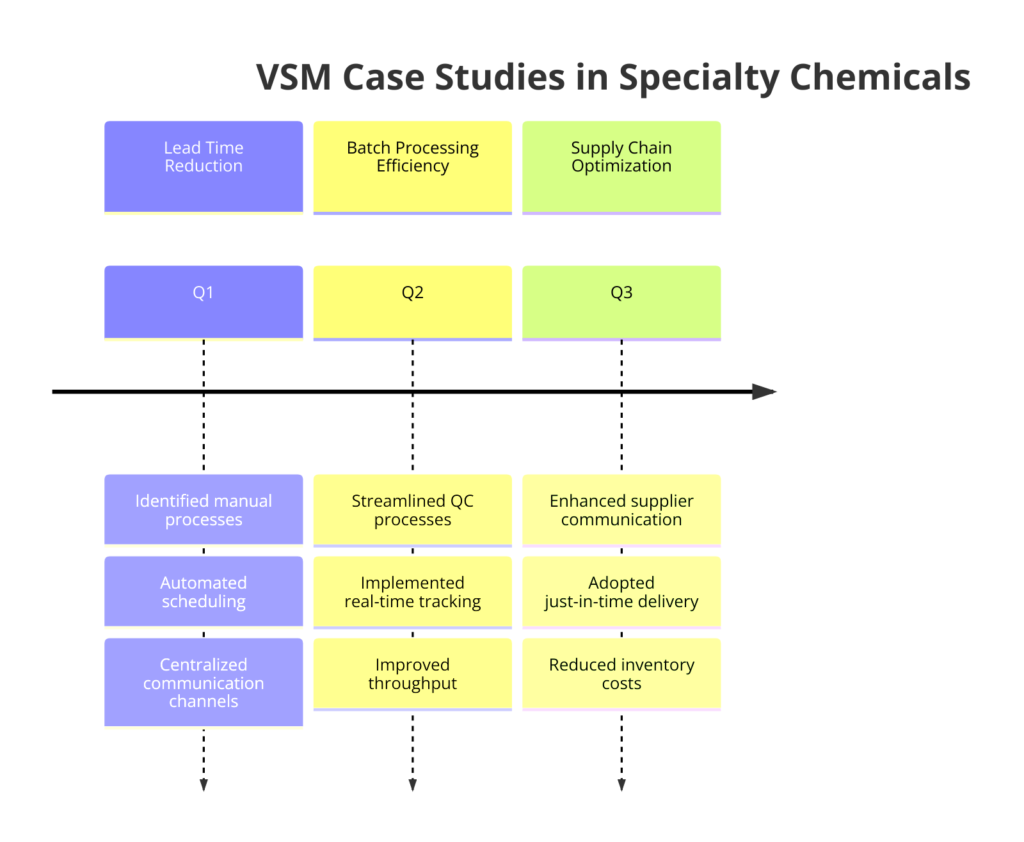

Cutting Lead Time on Special Formulations — Reduce Lead Time!

One specialty polymers manufacturer couldn’t deliver on tight deadlines because the order-processing and production processes were not optimized. With VSM, the firm discovered manual data entry and stale communication. Automated scheduling and centralized communications channels cut lead times by 25% which led to a better customer experience.

Improving Batch Processing Efficiency

One specialty resins company had inefficient batch mixing and QC processes. VSM exposed stale quality checks with little to no effect on the product. These processes were streamlined and with real-time tracking, the company increased throughput by 15%, and met increasing customer demand without further capital expenditure.

Optimizing Supply Chain Coordination

One specialty coatings company owed many different suppliers to critical raw materials, meaning that stock outs and production delays were common. VSM cited inaccurate delivery dates as the culprit. The company overhauled its purchasing system for just-in-time delivery and better supplier communication. These modifications made disruptions minimal and inventory holding much cheaper.

Solutions for Major Issues When Implementing VSM (and its Related Issues)

VSM is no easy task – particularly in an industry such as specialty chemicals. And the obstacle is resistance to transformation. Employees can’t be convinced to change or even believe the advantages. In order to counter this, organizations should involve employees early in the VSM journey and explain how the changes will benefit both the business and roles.

It is even scary to collect data, especially in multi-step process with so many variables. Data collection can be made easier and more accurate through digital platforms like analytics tools and IoT devices. And if not, departments need to collaborate so that they don’t create the silo effect of cross-functional innovation.

Enhancing VSM with Technology

With the help of technology, Value Stream Mapping is made more powerful through the in-depth, real-time performance measurement of the process. Equipment utilization and downtime can be monitored by IoT sensors for example, which will help in pinpointing bottlenecks. With advanced analytics solutions, teams can follow process in real-time so strategies can easily be changed accordingly.

The use of digital twins are another handy tool to make companies model the changes and implement them. One polymer specialty manufacturer used a digital twin to pilot different workflows, trying to figure out which was the fastest without breaking actual production. It kept risk low and got things done quickly.

Cloud solutions make VSM even better in that they make collaboration and transparency possible. Value stream maps are available to all teams and can be updated real-time for departmental coordination and decision making.

Sustaining and Scaling Improvements

Result through VSM is just the start. Maintaining these upgrades requires regular audits to keep processes running smoothly. A specialty resins company arranged quarterly revisions of its value stream maps, listening to employee input and solving new problems as they arise. Such continual tracking meant that performance remained stable for years to come.

Scaling improvements involves taking VSM to the company culture. Training, awarding achievements, and incentivizing employees to see opportunities for optimization is what keeps the momentum going. This strategy in the long run helps build an adaptive company.

Turning Insights into Action

Value Stream Mapping isn’t just a tool; it’s a mindset for the revolution in specialty chemicals manufacturing. When businesses visualize, identify the processes, and then drive specific optimizations, new possibilities of efficiency, innovation, and customer engagement open up. From streamlining lead times, batching or supply chain optimization, VSM is a road map for operational excellence and long-term expansion.